What Quality Standards Are Required for Wire Mesh Fence in South America?

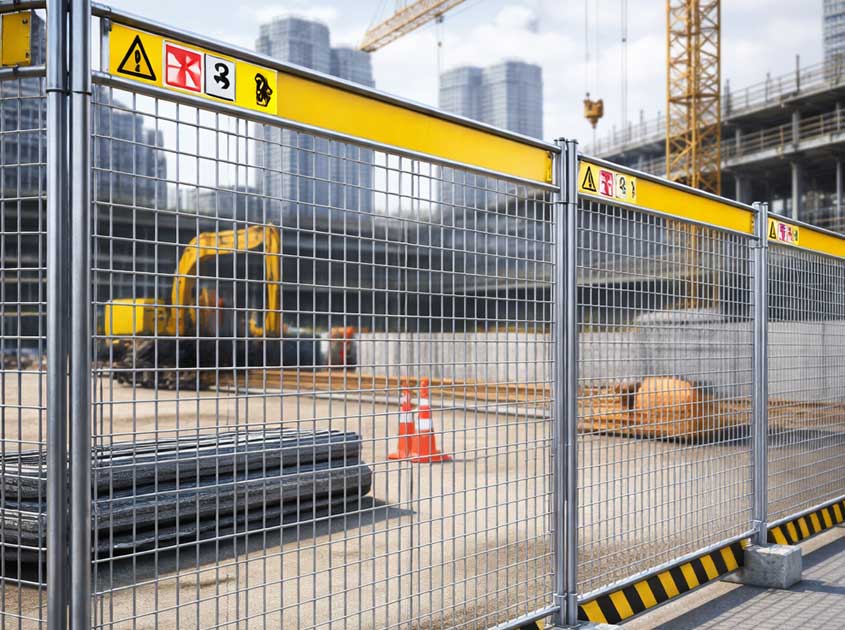

South America has become one of the fastest-growing markets for wire mesh fence systems due to expanding infrastructure, agriculture, mining, and residential construction. From Brazil and Argentina to Chile and Colombia, project owners and distributors increasingly demand certified, durable, and regulation-compliant fencing products.

Understanding quality standards is critical for importers, contractors, and manufacturers that supply wire mesh fencing to the South American market.

This guide explains the most important quality standards, testing requirements, and compliance expectations for wire mesh fences in South America.

Why Quality Standards Matter in South America

Wire mesh fences are used for:

Construction site security

Highway and railway protection

Agricultural fencing

Industrial and mining facilities

Residential and commercial developments

Poor-quality fencing leads to safety risks, corrosion failure, and legal liability. As a result, South American buyers increasingly require products that meet internationally recognized quality standards.

1. ISO 9001 – Manufacturing Quality Management

Most South American importers require suppliers to have ISO 9001 certification.

This standard ensures:

Controlled production processes

Material traceability

Welding and coating consistency

Quality inspection systems

Chinese wire mesh manufacturers with ISO 9001 are considered low-risk suppliers by distributors and contractors.

2. ASTM and EN Wire Mesh Fence Standards

Although South America does not have a single unified fence standard, most projects reference ASTM (American) or EN (European) standards.

Commonly accepted standards include:

Standard

Application

ASTM A641 Zinc-coated (galvanized) steel wire

ASTM A1064 Welded wire reinforcement

ASTM F668 Chain link fence wire

EN 10244 Coated steel wire

EN 10223 Steel wire products for fencing

These standards define:

Wire diameter tolerance

Tensile strength

Zinc coating weight

Weld shear strength

Corrosion resistance

South American engineering companies often require these values in technical documentation.

3. Galvanization and Coating Standards

Corrosion resistance is extremely important due to South America’s humid, tropical, and coastal climates.

Most buyers require:

Hot-Dip Galvanized

Zinc coating: 60–275 g/m²

Long-term rust protection

Suitable for outdoor and coastal environments

PVC or Powder Coated

Additional corrosion protection

Improved appearance

Often required for urban and residential fencing

Coating thickness and adhesion must comply with ASTM or EN coating standards.

4. Mechanical Performance Requirements

High-quality wire mesh fences must meet minimum mechanical strength values:

Tensile strength of wire

Weld shear strength

Mesh rigidity

Impact resistance

These tests ensure that the fence can resist:

Wind loads

Physical impact

Climbing and cutting

Long-term outdoor stress

Mining, highway, and industrial projects in Chile, Peru, and Brazil often specify these parameters in tenders.

5. Surface Finish and Visual Quality

South American construction projects—especially residential and commercial developments—require good appearance.

Quality inspection usually includes:

Smooth weld points

Uniform coating thickness

No sharp edges or burrs

No rust, bubbles, or peeling

This is especially important for PVC-coated and architectural fencing.

6. Environmental and Safety Compliance

Some projects require:

RoHS compliance

Lead-free coatings

Environmentally friendly powder coating

This is becoming more common in Brazil, Chile, and Colombia for government and commercial developments.

7. Export Documentation Required

South American importers usually require:

Mill test certificates (MTC)

Coating test reports

ISO certificates

Packing list and commercial invoice

Certificate of origin

A professional Chinese wire mesh exporter will provide these documents for customs clearance and project approval.

Why Chinese Manufacturers Can Meet These Standards

Modern Chinese wire mesh factories use:

Automated welding lines

Controlled galvanizing systems

Advanced powder coating plants

Laboratory testing equipment

This allows them to produce wire mesh fences that meet ASTM, EN, and ISO standards at competitive costs.

Conclusion

Wire mesh fences used in South America must meet international quality standards, including:

ISO 9001 manufacturing control

ASTM and EN technical standards

Hot-dip galvanization or PVC coating

Mechanical strength and corrosion resistance

Export and compliance documentation

By working with a certified Chinese wire mesh manufacturer, South American distributors and contractors can ensure their fencing systems are safe, durable, compliant, and competitive.

Latest News

Hot rolled coil slitting enhances efficiency through automated uncoilers and rewinders. Key methods include precision tension control, edge guidance systems, and IoT integration. These optimizations reduce downtime, improve material yield, and ensure high-quality slit coils for automotive and machinery industries.

2025-09-19

Cold rolled coil is essential in home appliance manufacturing. It expertly combines thin gauge for lightweight, energy-efficient designs with high strength from optimized steel processing. This balance enables durable, high-performance appliances like refrigerators and washing machines, supporting industry trends towards sustainability and advanced production.

2025-09-17

Aluzinc coil offers exceptional corrosion resistance and weathering properties, making it ideal for photovoltaic mounting systems. Wholesale prices depend on material composition and market factors. Its applications in solar projects ensure durability and cost savings. Procurement should focus on certified suppliers and tailored specifications for optimal performance.

2025-09-11

The article discusses the selection and application of spring steel plates, like 65Mn, for automotive lightweighting. It covers heat treatment processes and key procurement considerations, emphasizing performance and durability in vehicle systems.

2025-09-08

The slitting process significantly impacts stainless steel strip material utilization. Optimizing techniques like precision cutting and smart layout planning boosts efficiency, reduces waste, and lowers production costs.

2025-09-05

Cost-Benefit Analysis of Aluzinc-Coated Steel vs. Galvanized Steel in Color Steel Tile Production

Aluzinc-coated steel offers superior corrosion resistance and longer service life than traditional galvanized steel, reducing long-term costs in color steel tile production. Despite higher initial prices, its durability and lower maintenance make it a cost-effective alternative. Manufacturers should evaluate environmental needs and lifecycle costs to choose between materials, ensuring optimal performance and competitiveness.

2025-09-03